Tackling Aerodynamic Challenges for a Greener Future in Transport.

The Problem

Excessive emissions, fuel consumption, and limited range for road transport.

Recent statistics indicates that the transportation sector is responsible for 24% of greenhouse gas emissions in the UK, with over 80% coming from road vehicles. When vehicles move, up to 65% of the energy they use is to overcome aerodynamic drag. The main problem with truck and lorry aerodynamics today include:

Environmental

In addressing climate change, reducing emissions and fuel consumption and extending the range in road transport is essential. Trucks contribute approximately 30% of total greenhouse gas emissions within the transportation sector. Overcoming aerodynamic drag accounts for roughly 50% of the energy produced by a truck’s engine, irrespective of the type of fuel used, emphasizing the importance of optimizing aerodynamic efficiency and turbulent flows.

Engineering

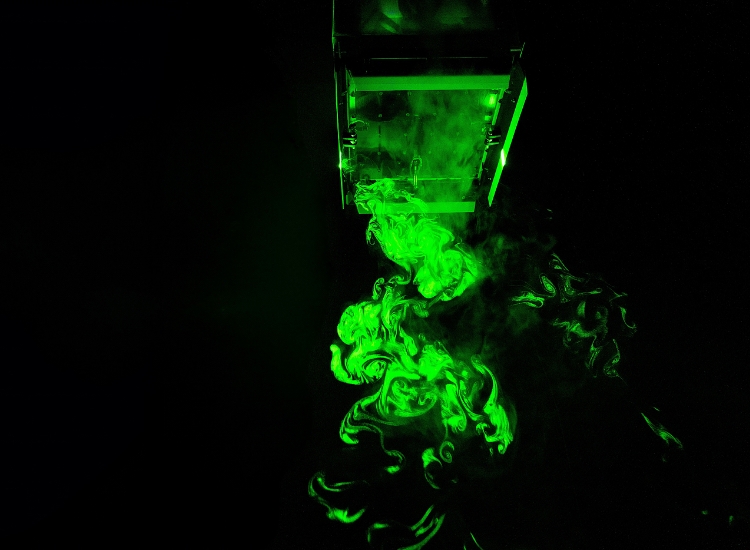

Turbulence, the oldest unsolved problems, is ubiquitous in systems underpinning transition to net zero and is the main cause of aerodynamic losses. Enhancing efficiency therefore depends on predicting and controlling turbulent flows, even under limited information. However, the inherently complex, unpredictable, and high-dimensional nature of turbulence has thus far prevented the development of devices or algorithms that can reliably adapt to variable conditions in real-world turbulent environments.

The Solution

REAL-TIME DECISION-MAKING TOOLS TO ENABLE ACTIVE AERODYNAMIC OPTIMISATION.

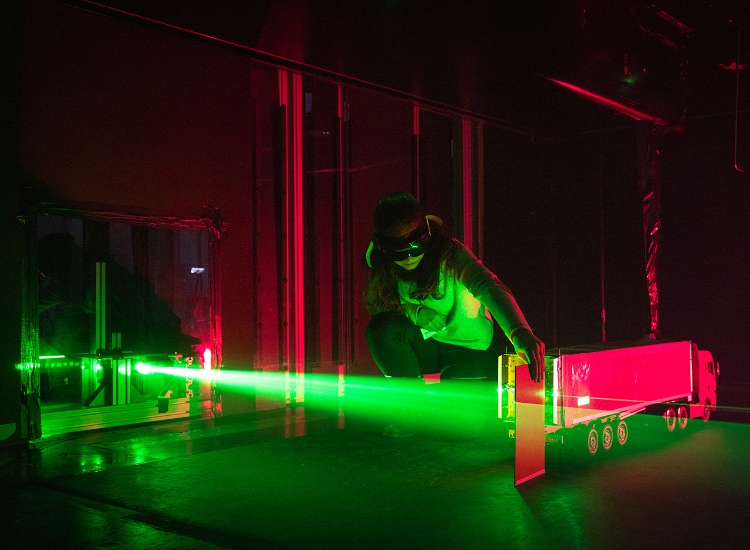

We are using novel autonomous, dynamically adjustable flaps, controlled by AI, on the rear of heavy road vehicles to reduce drag by adapting in real time to turbulence and changing external conditions. The flaps autonomously adjust to maximum drag reduction and enhance vehicle efficiency.

The state-of-the-art AI controller, based on a reinforcement learning technique, has been integrated into the flap system. This algorithm learns from limited observations to continually fine-tune the flap positioning and respond optimally to the complex, turbulent flow.

Current solution, static flaps, can reduce drag by 10% (at their optimised design point. When the external conditions are changed these devices become less efficient.

Our solutions improve the efficiency by 2 to 3 times respect to the static case (estimation from preliminary experiments).

The adaptability of the mechanism guarantees the optimal configuration in variable situation.

Reducing fuel consumption and emissions, reduces the cost of transportation of goods.

It is estimated that 50% of the truck engine power is needed to overcome the aerodynamic drag of a Heavy Goods Vehicle (HGV) at a typical highway speed of 90-100 km/h1 (regardless of fuel type).

A drag reduction of 10% results in a reduction in fuel consumption.

RESEARCH TEAM

Dr George Rigas

Road Transport

Isabella Fumarola

Road Transport

Max Weissenbacher

Digital Twins

Xianyang Jiang

Road Transport

Anton Plaksin

Road Transport